Dry Ice Blasting: The Future of Industrial Cleaning

Introduction to Dry Ice Blasting

Industrial cleaning is a critical aspect of maintaining machinery, equipment, and facilities. Traditional cleaning methods, such as water-based or chemical cleaning, often have limitations, such as the potential for corrosion or residue buildup. Dry ice blasting has emerged as a groundbreaking solution to these problems, offering a cleaner, more efficient, and eco-friendly method for industrial cleaning.

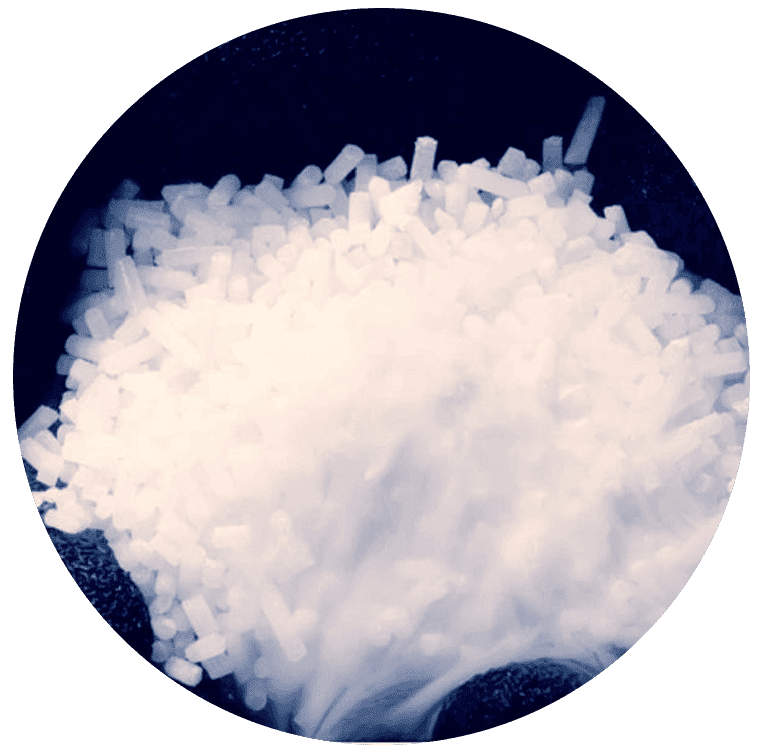

Dry ice blasting uses solid CO₂ (carbon dioxide) pellets propelled at high speeds to clean surfaces without damaging or leaving residue. This method is gaining traction across various industries due to its versatility, efficiency, and environmental benefits.

How Dry Ice Blasting Works

Dry ice blasting is a non-abrasive cleaning method that relies on the combination of three main effects: kinetic energy, thermal shock, and sublimation.

- Kinetic Energy: When dry ice pellets are shot at high velocities, they create an impact that dislodges dirt, grease, and contaminants from the surface being cleaned.

- Thermal Shock: Dry ice is extremely cold (approximately -78°C or -109°F). When the pellets come in contact with contaminants, the extreme temperature causes them to crack and break away from the surface.

- Sublimation: The dry ice pellets rapidly transition from solid to gas, which helps lift contaminants off the surface. The process of sublimation leaves no residue behind, making it a dry, clean solution for sensitive equipment.

The combination of these three effects makes dry ice blasting a superior cleaning method for delicate and hard-to-reach areas, where traditional methods might fail.

The Advantages of Dry Ice Blasting

1. Non-Abrasive and Safe for Sensitive Equipment

Unlike traditional abrasive cleaning methods, such as sandblasting or wire brushing, dry ice blasting does not cause damage to the surface. It cleans effectively without scratching or eroding delicate materials. This makes it perfect for cleaning sensitive machinery in industries such as aerospace, electronics, and food processing, where preserving the integrity of components is essential.

2. Residue-Free Cleaning

One of the most appealing aspects of dry ice blasting is that it leaves no residue behind. The CO₂ pellets sublimate upon impact, turning directly into gas, so there is no waste or residue to clean up afterward. This is a huge advantage in environments where cleanliness and contamination control are paramount, such as in medical, pharmaceutical, or food production facilities.

3. Environmentally Friendly

Dry ice blasting is an eco-friendly cleaning solution. Unlike chemical cleaning, which often produces hazardous waste, dry ice blasting requires no chemicals and produces no wastewater. Additionally, the CO₂ used in the process is typically captured from other industrial processes, making it a sustainable, carbon-neutral method. This contributes to reducing your facility’s environmental footprint.

4. Minimal Downtime and Increased Efficiency

Traditional cleaning methods often require disassembling machinery or shutting down equipment, leading to significant downtime. With dry ice blasting, most cleaning can be done without the need for disassembly, allowing equipment to remain operational. This increases productivity and minimizes disruptions to your operations.

5. No Need for Water

Water-based cleaning methods can damage electrical components or leave moisture behind, leading to rust or mold growth. Dry ice blasting is a completely dry process, making it safe for use on electronics, electrical equipment, and other sensitive machinery. It also eliminates the need for costly water treatment or disposal systems.

Key Applications of Dry Ice Blasting

Dry ice blasting is highly versatile and can be used in various industries. Some of the most common applications include:

1. Food Processing Industry

In food production, cleanliness is of utmost importance. Dry ice blasting is used to clean conveyors, ovens, mixers, and other food-processing equipment without introducing moisture or chemicals that could contaminate the products. It is also highly effective for removing sticky residues, such as grease, sugar, and oils, that accumulate during food production.

2. Automotive Industry

In the automotive sector, dry ice blasting is used to clean engine parts, molds, and other components that require precision cleaning. It helps remove oil, grease, carbon, and other contaminants that can affect the performance and longevity of automotive parts. It’s a quick and efficient way to maintain the cleanliness of manufacturing equipment and parts during production.

3. Aerospace and Aviation

The aerospace industry relies on dry ice blasting to clean turbine blades, aircraft engines, and other sensitive parts without causing damage. Given the high precision required in the aerospace sector, dry ice blasting is ideal as it effectively removes contaminants without leaving any residue that could affect performance or safety.

4. Electronics Manufacturing

In electronics manufacturing, cleanliness is crucial to prevent short circuits and other malfunctions. Dry ice blasting is used to clean circuit boards, electrical components, and assembly lines without the risk of moisture damage. The non-abrasive nature of the technique makes it ideal for delicate electronic components that could be harmed by more aggressive cleaning methods.

5. Restoration and Remediation

In restoration and remediation, dry ice blasting is used to remove soot, mold, smoke, and other contaminants from surfaces following a fire or flood. It is highly effective at cleaning structural materials like wood, stone, and concrete, and it does so without causing further damage to the property. It is a safer, more effective option than traditional cleaning methods such as pressure washing or chemical cleaning.

Safety Considerations When Using Dry Ice Blasting

While dry ice blasting is a safe and efficient cleaning method, there are certain precautions to take to ensure the safety of the workers:

- Personal Protective Equipment (PPE): Operators should wear gloves, eye protection, and appropriate clothing to avoid cold burns from handling dry ice.

- Ventilation: Adequate ventilation is important, especially in enclosed spaces, as CO₂ gas can displace oxygen. Ensuring proper airflow is crucial to prevent the risk of asphyxiation.

- Training: Workers should be properly trained in handling dry ice and using the equipment to ensure safety and achieve optimal cleaning results.

Dry Ice Blasting vs. Traditional Cleaning Methods

When compared to traditional methods like sandblasting, pressure washing, and chemical cleaning, dry ice blasting offers several key advantages:

- Non-toxic and chemical-free: Traditional methods often rely on harmful chemicals, while dry ice blasting requires no toxic substances, making it a safer and more sustainable choice.

- No moisture: Water-based cleaning methods can damage equipment or create additional issues like rusting or mold growth. Dry ice blasting is completely dry, eliminating these risks.

- No secondary waste: Sandblasting and other abrasive methods can leave behind debris or particles that require further cleanup. Dry ice sublimates, leaving only the contaminants behind.

Conclusion

Dry ice blasting is transforming industrial cleaning by offering a highly effective, safe, and environmentally friendly alternative to traditional cleaning methods. Its non-abrasive nature, residue-free results, and efficiency make it a go-to solution for industries that require the highest standards of cleanliness. Whether you’re in food production, automotive manufacturing, aerospace, or restoration, dry ice blasting provides a fast, efficient, and eco-conscious cleaning solution for modern businesses.

If you’re looking to improve productivity, reduce environmental impact, and maintain your equipment without compromising on quality, dry ice blasting is the answer.