Semi-automatic L sealer machines are an essential part of modern packaging processes, offering versatility and efficiency for different industries. These machines are designed to work with a variety of shrink films, each catering to different packaging needs. Whether businesses need strong protection, high clarity, or eco-friendly options, semi-automatic L sealers can handle diverse materials with ease.

This article will explore how these machines support various film types, their compatibility with different industries, and why they are an ideal choice for businesses looking to optimize their packaging operations.

Understanding Semi-Automatic L Sealer Machines

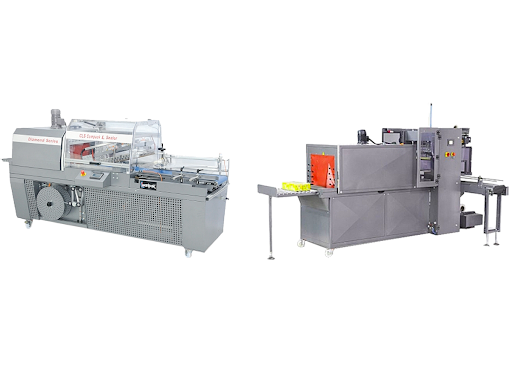

A semi-automatic L sealer machine is used in packaging to wrap products in shrink film before heat sealing and shrinking. The machine cuts and seals the film around the product, which is then passed through a heat tunnel for shrink wrapping. This type of machine strikes a balance between manual control and automation, making it suitable for businesses with moderate production volumes.

These machines can work with multiple types of shrink film, ensuring flexibility across industries such as food packaging, pharmaceuticals, electronics, and retail.

Types of Films Supported by Semi-Automatic L Sealer Machines

1. Polyolefin (POF) Shrink Film

Polyolefin is one of the most popular shrink films due to its strength, clarity, and FDA compliance for food packaging. Semi-automatic L sealers are well-suited for handling POF film as they can create clean and durable seals.

- Benefits of POF Film in L Sealers:

- Strong and puncture-resistant

- High clarity for attractive packaging

- Safe for direct food contact

- Suitable for multi-packaging

2. PVC Shrink Film

PVC shrink film was traditionally popular for packaging, but its use has declined due to environmental concerns. However, semi-automatic L sealers still accommodate PVC film for industries that require a cost-effective shrink-wrapping solution.

- Advantages of PVC Film in L Sealers:

- Excellent clarity and gloss

- High shrink rate

- Cost-effective for non-food applications

3. Polyethylene (PE) Shrink Film

Polyethylene is a durable shrink film primarily used for heavier and larger products. Semi-automatic L sealers support PE film but often require minor modifications or specialized sealing blades to ensure a proper seal.

- Why Use PE Film in L Sealers?

- Ideal for bundling multiple products

- Strong and resistant to tearing

- Used in industrial packaging

4. Biodegradable and Eco-Friendly Films

As sustainability becomes a priority, many businesses are switching to biodegradable shrink films. Semi-automatic L sealer machines can support these films with proper heat settings to avoid degradation during sealing.

- Advantages of Eco-Friendly Films:

- Reduces environmental impact

- Compliant with sustainability regulations

- Suitable for brands with green initiatives

5. Cross-Linked Polyolefin Shrink Film

Cross-linked POF film offers even more durability than standard POF. It is commonly used in high-speed packaging and is ideal for protecting products from external damage.

- Why Choose Cross-Linked POF?

- Higher strength for heavy-duty applications

- Enhanced clarity and presentation

- Works well with semi-automatic L sealers for high-end packaging

6. Perforated Shrink Films

Perforated shrink films allow air to escape during the shrink-wrapping process, preventing air bubbles and wrinkles. Semi-automatic L sealer machines can handle perforated films without additional adjustments.

- Key Benefits:

- Smooth shrink finish

- Ideal for products requiring ventilation

- Prevents trapped air pockets

7. Pre-Printed Shrink Films

Brands often use pre-printed shrink films for marketing and branding purposes. Semi-automatic L sealers accommodate these films while ensuring that branding elements remain visible and undistorted.

- Advantages of Pre-Printed Films:

- Enhances product branding

- Eliminates the need for additional labeling

- Customizable for seasonal promotions

Choosing the Right Film for Your Packaging Needs

Selecting the appropriate film for a semi-automatic L sealer depends on various factors, including product type, packaging durability, and environmental considerations. Here’s how different industries benefit from the versatility of L sealer machines:

- Food & Beverage: POF film ensures safe, transparent, and attractive packaging.

- Electronics: Cross-linked POF protects devices from dust and damage.

- Retail & E-commerce: Pre-printed and high-clarity films enhance brand visibility.

- Pharmaceuticals: Medical products require tamper-proof and FDA-approved films.

In addition to semi-automatic L sealers, businesses often use an automatic side sealing machine for high-speed, continuous sealing applications. While L sealers provide precise packaging for moderate production volumes, automatic side-sealing machines are ideal for businesses requiring faster operations with minimal manual intervention.

Conclusion

Semi-automatic L sealer machines are highly adaptable, supporting a wide range of film types to meet diverse packaging needs. Whether businesses require durability, eco-friendliness, or cost-effectiveness, these machines ensure efficient sealing and shrink wrapping for different industries. By selecting the right shrink film, companies can optimize their packaging operations and enhance product presentation.

For high-quality L sealer machines and shrink packaging solutions, Maripak USA provides industry-leading equipment designed for precision and efficiency.