Air valves play a critical role in many mechanical systems, including automotive engines, HVAC units, and pneumatic tools. Over time, these components can wear out, causing performance issues or complete system failure. Fortunately, with the right tools and knowledge, replacing worn air valves with valve kits is a manageable DIY project or maintenance task. This article walks you through how to identify worn air valves and how to replace them efficiently using air valves and valve kits.

What Are Air Valves and Valve Kits?

Before we jump into diagnostics and replacement, let’s understand what air valves and valve kits are.

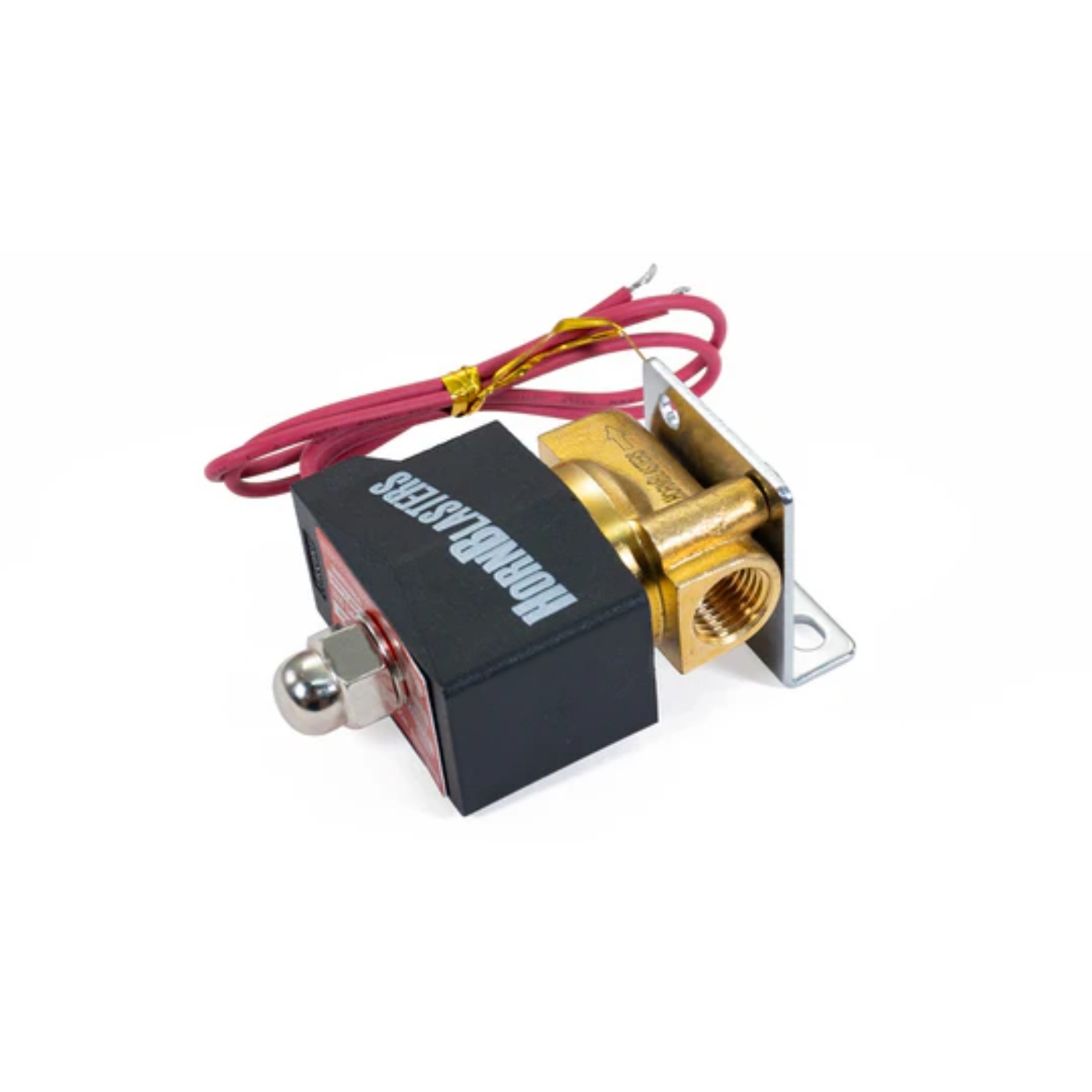

Air valves are mechanical devices that regulate the flow of air within a system. Depending on the application, they may control air intake, exhaust, pressure, or direction. You’ll find them in everything from internal combustion engines and air compressors to air suspension systems and industrial machinery.

A valve kit typically includes everything needed to service or replace an air valve, such as seals, springs, gaskets, and the valve body itself. Using valve kits ensures you have the correct components and helps extend the life of your system.

Common Signs of Worn Air Valves

Air valves can degrade slowly over time or fail suddenly. Here are some common symptoms that indicate your air valves may be worn out:

1. Loss of Pressure or Performance

If you notice a decrease in air pressure, slower operation, or less power in pneumatic tools or machinery, a faulty air valve could be the culprit. This issue often arises from worn internal seals or damaged valve seats.

2. Hissing or Air Leaks

A hissing noise is a red flag. It often points to air leaking from the valve. Over time, O-rings and gaskets can crack or wear out, allowing air to escape.

3. Sticky or Unresponsive Operation

If your air valve becomes sticky or fails to respond to input, internal parts might be gummed up with debris or simply worn out. This symptom is particularly common in valves exposed to moisture or dust.

4. Erratic Behavior

Intermittent function or unpredictable performance in systems relying on air pressure could indicate that the air valves are no longer working consistently.

How to Inspect Your Air Valves

Once you notice signs of trouble, it’s time for a closer inspection. Follow these steps to assess the condition of your air valves:

Step 1: Shut Down the System

Always start by turning off and depressurizing the system to avoid injury or damage.

Step 2: Remove the Air Valve

Using the appropriate tools, carefully remove the air valve from the system. Make note of its orientation and placement to ensure proper reinstallation.

Step 3: Examine the Components

Check for visible damage such as cracks, corrosion, or debris buildup. Inspect the seals and gaskets for signs of wear, hardening, or breakage.

Step 4: Test Manually

If the valve is mechanical (e.g., spring-loaded), test its movement manually. It should open and close smoothly without resistance or sticking.

Choosing the Right Air Valve Kit

Not all air valves valve kits are universal. Selecting the right kit depends on your specific system. Here are some tips:

-

Check the Model Number: Match the air valve’s model number with the replacement kit. Manufacturers often list compatible valve kits for each part number.

-

Know the Application: Valve kits for automotive engines will differ from those used in HVAC systems or industrial equipment.

-

Look for Quality Materials: Choose kits made from high-quality materials like stainless steel, Viton seals, or brass components to ensure durability.

Buying a comprehensive kit often saves time and frustration compared to sourcing individual parts.

How to Replace Worn Air Valves with Valve Kits

Once you’ve identified the faulty valve and chosen the right kit, follow these general steps for replacement:

Step 1: Gather Tools and Materials

You’ll typically need:

-

A wrench set

-

Screwdrivers

-

Cleaning brush or rag

-

Lubricant (if specified by the kit)

-

The new air valve kit

Step 2: Clean the Area

Before installing the new parts, clean the valve housing and surrounding area. Dirt or old gasket residue can affect the seal and function of your new valve.

Step 3: Install New Components

Following the instructions in your valve kit:

-

Replace worn O-rings, gaskets, or springs.

-

Insert the new valve body if included.

-

Ensure all components are seated properly.

Pay close attention to alignment—improper installation can lead to leaks or poor performance.

Step 4: Reassemble and Tighten

Reinstall the valve into its original position. Tighten it securely, but don’t over-torque, which can crack housings or damage threads.

Step 5: Test the System

After reassembly, repressurize the system and observe the valve in operation. Listen for leaks, and check if the issue you originally identified is resolved.

Preventive Maintenance Tips

Replacing worn air valves is one thing—but preventing premature wear is even better. Here are some maintenance tips to keep your system in top shape:

-

Regular Inspections: Periodically check air valves and seals for early signs of wear.

-

Clean Air Supply: Use air filters and moisture traps to keep contaminants from damaging valves.

-

Lubrication: Some valves require light lubrication. Check the manufacturer’s guidelines and lubricate as needed.

-

Use the Right Pressure: Operating a system outside of its pressure rating can wear valves faster than normal.

When to Call a Professional

While replacing air valves and valve kits is often DIY-friendly, some systems—especially complex industrial machinery or high-pressure setups—are best handled by a qualified technician. If you’re unsure about what you’re doing or notice unusual system behavior after replacement, don’t hesitate to call for expert help.

Conclusion

Keeping your equipment running smoothly starts with knowing how to spot trouble early. Worn air valves can wreak havoc on system performance, but with the right tools and air valves and valve kits, you can tackle the problem head-on. Whether you’re working on a compressor, pneumatic tool, or HVAC system, proper valve maintenance and timely replacement will save you time, money, and headaches down the road. So next time your system starts acting up, remember: a quick inspection and the right valve kit might be all it takes to get things running like new again.