What is Precast Detailing & Why It Matters

Precast detailing is the precise design and detailing of precast concrete elements before they are manufactured in a controlled environment. This step ensures every component fits perfectly when assembled at the construction site, reducing errors, waste, and delays.

Why Is Precast Detailing Essential?

- Precision & Accuracy: Eliminates costly mistakes and misalignments.

- Faster Construction: Reduces on-site work, accelerating project timelines.

- Cost-Effective: Lowers material waste and labor costs.

- Enhanced Safety: Factory-controlled manufacturing improves quality and reduces defects.

Where Is Precast Concrete Used?

Precast concrete is a fundamental part of modern construction, appearing in:

- Commercial Buildings: Malls, office buildings, warehouses.

- Residential Projects: Apartments, housing complexes.

- Infrastructure: Bridges, tunnels, metro stations.

- Industrial Facilities: Factories, storage units, parking structures.

Key Components in Precast Concrete Structures

- Precast Slabs: Used for floors and ceilings (hollow-core, solid, or double-tee slabs).

- Precast Columns & Beams: Provide structural support.

- Precast Walls: Load-bearing or non-load-bearing panels.

- Precast Stairs & Landings: Precast staircases for buildings.

Each component is manufactured, transported, and assembled on-site, ensuring efficiency and consistency.

Precast Concrete vs. Traditional Cast-in-Place Concrete

| Feature | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Speed | Faster production & installation | Slower due to on-site pouring |

| Quality Control | Factory-controlled precision | Weather & human error risks |

| Cost Efficiency | Reduces waste & labor costs | Higher due to on-site work |

| Durability | Stronger due to controlled curing | Prone to inconsistencies |

Step-by-Step Process of Precast Detailing

1. Understanding Project Requirements

Engineers and architects outline project specifications and expectations.

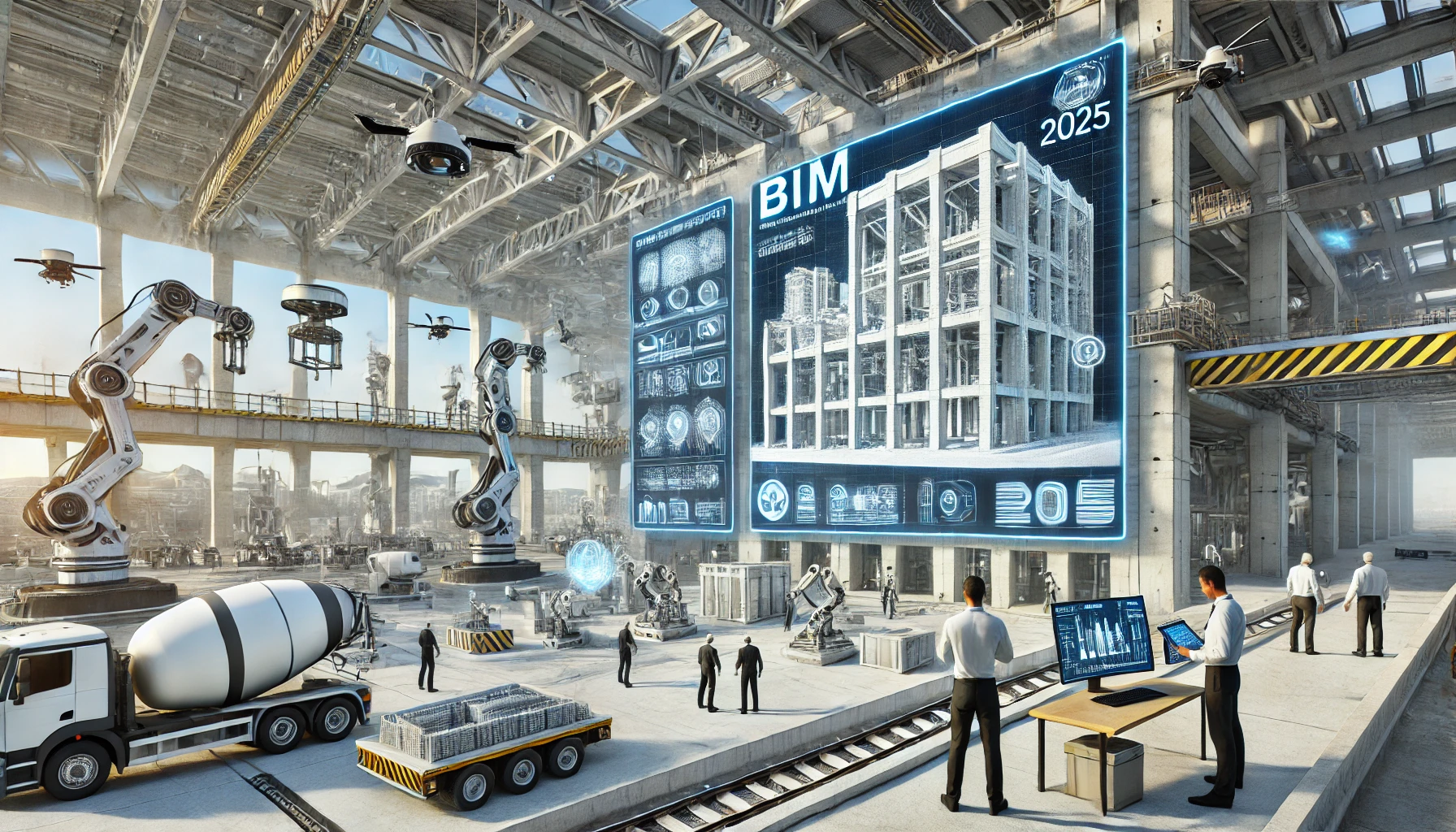

2. Creating 3D Models

Using Building Information Modeling (BIM) software, engineers develop precise 3D models to visualize the structure.

3. Generating Shop Drawings

Detailed drawings guide manufacturing, ensuring accuracy and efficiency.

4. Adding Reinforcement Details

Steel reinforcements are integrated for structural strength and durability.

5. Reviewing & Approving Designs

Final checks prevent costly manufacturing mistakes before production starts.

Best Software for Precast Detailing

- Tekla Structures: Leading BIM-based precast detailing tool.

- AutoCAD: Ideal for 2D & 3D precast design.

- Revit: Advanced 3D modeling and visualization.

- StruCAD, Allplan Precast, BricsCAD: Additional software for specialized detailing.

These tools ensure precision, reduce errors, and optimize the detailing workflow.

Challenges in Precast Detailing & Solutions

| Challenge | Solution |

| Dimensional Accuracy Issues | Use 3D modeling software for early error detection. |

| Connection Complexity | Standardize joint designs to simplify assembly. |

| Transportation & Handling Problems | Optimize element sizes for efficient transport. |

How to Overcome These Challenges?

By leveraging automation, digital twin technology, and industry best practices, precast detailing can be made more reliable and cost-effective.

Future Trends in Precast Detailing

🚀 Automation & AI: AI-driven detailing reduces human errors and enhances precision. 📌 3D Printing: Enables rapid production of precast elements. 🌍 Sustainability: Adoption of eco-friendly materials to reduce environmental impact. 🔍 Digital Twins: Real-time monitoring for better quality control and project management.

Final Thoughts: The Future of Precast Detailing

Precast detailing is revolutionizing the construction industry by making buildings stronger, more cost-effective, and faster to build. With the integration of cutting-edge technologies and best practices, the future of precast concrete detailing is poised for greater efficiency and precision.

For expert precast detailing services, reach out to our team and ensure flawless execution for your next project.

Learn about CAD & BIM Services – The Future of Construction & Design