As a writer and researcher specializing in industrial mobility solutions, I have explored the vast landscape of advanced caster technologies. One of the most revolutionary innovations in this field is motorized caster wheels. These components are transforming industries by enhancing mobility, increasing efficiency, and reducing manual labor. But how do you determine the best custom motorized caster wheels for your specific needs? This guide will break down essential factors to consider and highlight some of the best options available.

Understanding Motorized Caster Wheels

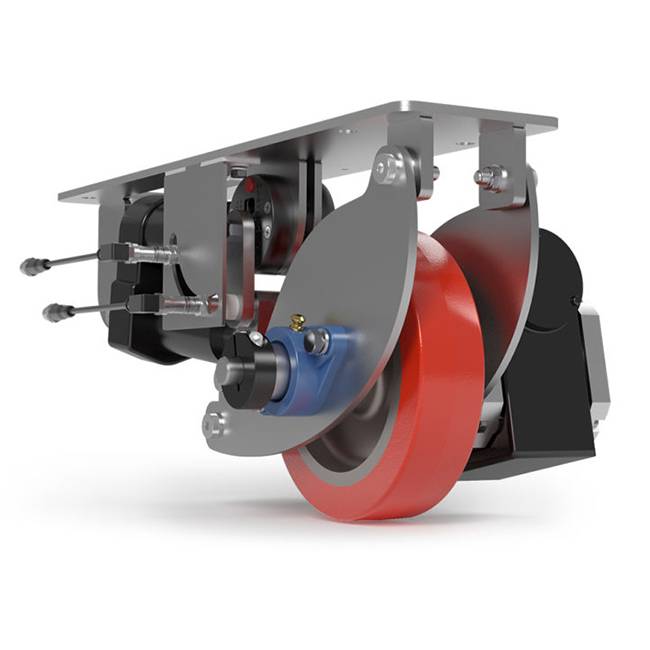

Motorized caster wheels are integrated with electric-powered drive mechanisms that enable automated movement and control. These wheels eliminate the need for manual pushing and pulling, reducing workplace injuries and improving productivity. They are widely used in various industries, including manufacturing, warehousing, healthcare, and material handling.

Factors to Consider When Choosing Custom Motorized Caster Wheels

Customization is key when selecting motorized caster wheels for your application. Here are crucial aspects to evaluate:

1. Load Capacity

Different applications require caster wheels capable of handling various weight limits. Heavy-duty operations such as industrial manufacturing and logistics demand wheels that can support significant loads without compromising performance.

2. Wheel Material

The choice of material impacts durability, traction, and resistance to wear and tear. Common materials include:

- Polyurethane: Ideal for smooth, quiet operation with excellent durability.

- Rubber: Provides superior grip and shock absorption.

- Nylon: Suitable for high-load applications with minimal rolling resistance.

3. Power and Control Mechanisms

Motorized caster wheels come with different drive systems. Some are equipped with:

- Battery-powered motors for enhanced mobility.

- Remote-controlled systems for precise maneuverability.

- Programmable logic controllers (PLCs) for automated operations.

4. Environmental Considerations

The working environment plays a significant role in choosing the right caster wheels. Factors such as temperature variations, moisture levels, and chemical exposure should be evaluated to ensure longevity and reliability.

5. Speed and Mobility Requirements

Motorized caster wheels vary in speed capabilities, depending on the intended application. Some industries require slow, controlled movement, while others may need faster mobility for efficiency.

6. Safety Features

Safety is paramount when selecting caster wheels. Look for features such as:

- Braking systems for controlled stopping.

- Obstacle detection sensors to prevent collisions.

- Emergency stop functions to enhance workplace safety.

Top Custom Motorized Caster Wheels for Different Applications

1. Heavy-Duty Industrial Motorized Caster Wheels

These are designed for large-scale material handling and manufacturing plants. They offer:

- High load-bearing capacity.

- Enhanced durability for rugged environments.

- Precision control with programmable movement.

2. Ergonomic Medical Motorized Caster Wheels

Hospitals and healthcare facilities require smooth, quiet, and efficient mobility solutions. These caster wheels provide:

- Low noise operation for patient comfort.

- Anti-microbial materials for hygiene.

- Intuitive controls for ease of use by medical staff.

3. Smart Automated Warehouse Caster Wheels

Warehouses and distribution centers benefit from motorized caster wheels integrated with AI and IoT for automated logistics. Key features include:

- Wireless connectivity for smart navigation.

- Adaptive speed control for optimal performance.

- Energy-efficient battery management systems.

4. Compact and Lightweight Motorized Caster Wheels for Retail

Retail settings often require small, maneuverable wheels for automated carts and trolleys. These wheels offer:

- Silent movement to enhance customer experience.

- Compact design for narrow aisles.

- Easy integration with automated shopping systems.

Customization Options for Enhanced Performance

Customizing motorized caster wheels allows for greater adaptability and efficiency. Some customization options include:

- Wheel diameter adjustments for different terrain types.

- Shock absorption enhancements for delicate cargo transportation.

- Tailored speed settings for specific industry needs.

- Integrated tracking systems for real-time monitoring.

The Future of Motorized Caster Wheels

With advancements in robotics and artificial intelligence, the future of motorized caster wheels is promising. Autonomous mobility solutions are evolving rapidly, and industries are embracing automation to improve efficiency and reduce costs. Future developments may include:

- AI-driven navigation systems for intelligent route planning.

- Enhanced battery technologies for extended operation times.

- Seamless integration with smart factory solutions for industry 4.0 compliance.

Conclusion

Selecting the best custom motorized caster wheels depends on your industry requirements, environmental factors, and operational needs. By considering load capacity, wheel materials, control mechanisms, and safety features, you can optimize mobility and enhance productivity. As technology advances, these caster wheels will continue to revolutionize industries, offering smarter, safer, and more efficient mobility solutions.

As a dedicated researcher in this field, I have examined various solutions and their impact on different industries. Investing in the right motorized caster wheels can significantly improve operational efficiency, reduce manual labor, and enhance workplace safety. With the right customization, your business can stay ahead of the competition in the evolving landscape of industrial mobility.