Introduction

Precision is everything when it comes to lamination rotor stacking. These components form the backbone of electric motors, generators, and transformers. Any slight misalignment in the rotor stack can lead to increased energy loss, reduced efficiency, and mechanical failure. That’s where CNC machining plays a crucial role.

With advanced CNC technology, manufacturers can ensure that every rotor stack meets exact specifications, allowing for high-performance applications in aerospace, automotive, and industrial sectors. This blog explores how CNC machining enhances the quality and reliability of rotor stacks.

Understanding Lamination Rotor Stacking

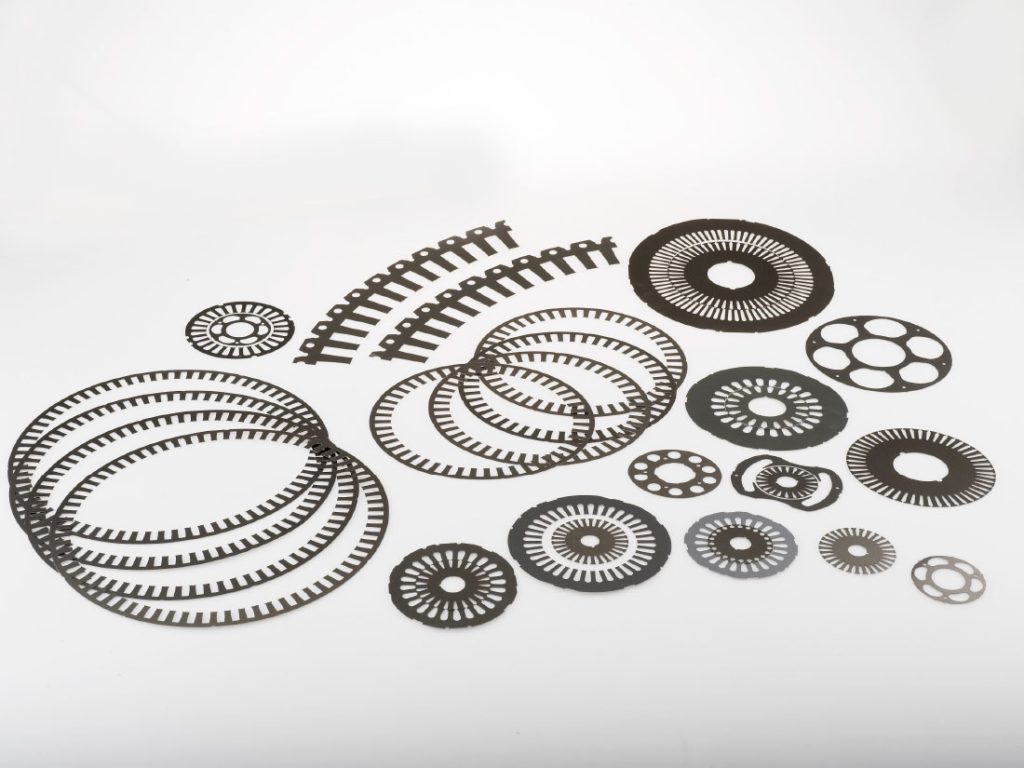

Lamination rotor stacking is the process of layering thin metal sheets, or laminations, to form the core of a motor’s rotor. These laminations are typically made from silicon steel, nickel alloys, or cobalt alloys. The goal is to reduce energy losses caused by eddy currents while maintaining structural integrity and durability.

Manufacturers use various techniques to assemble rotor stacks, including:

- Bonding – Using adhesives or resins to hold laminations together.

- Riveting – Fastening laminations with rivets for a secure fit.

- Welding – Fusing laminations to prevent movement.

- Staking – Mechanically pressing laminations into position.

Each method requires extreme precision, which is why CNC machining is essential in achieving the tight tolerances needed for optimal performance.

The Role of CNC Machining in Rotor Stack Manufacturing

CNC machining provides the accuracy and consistency needed for rotor stacking. Here’s how it improves the manufacturing process:

- Precision Cutting for High-Performance Rotor Stacks

Laminations must be cut with extreme precision to ensure a perfect fit within the rotor assembly. CNC machining offers:

- Laser cutting and wire EDM for intricate designs and tight tolerances.

- Consistent shaping of laminations to prevent misalignment in the stack.

- Improved efficiency by reducing material waste and production errors.

- Perfectly Aligned Stacking for Enhanced Performance

Stacking imperfections can lead to vibration, noise, and mechanical inefficiencies. CNC machining helps in:

- Ensuring tight tolerances in lamination thickness and alignment.

- Reducing core losses by keeping laminations perfectly aligned.

- Enhancing durability by maintaining uniform pressure throughout the stack.

- CNC Grinding for Superior Surface Finish

The final step in rotor stack manufacturing often involves CNC grinding to:

- Achieve smooth surfaces for better conductivity and reduced friction.

- Ensure uniform rotor balance to prevent unwanted vibrations.

- Improve core insulation properties, enhancing overall motor performance.

Advantages of CNC Machining in Rotor Stack Manufacturing

CNC machining isn’t just about precision—it also offers several benefits that improve rotor stack quality and performance.

- High Repeatability and Consistency

Once a CNC machine is programmed, it can produce thousands of identical parts with minimal variation. This ensures that every rotor stack meets exact specifications, reducing performance inconsistencies.

- Cost-Effective Production

Although CNC machining requires an initial investment, it reduces costs in the long run by:

- Minimizing material waste.

- Reducing rework and rejected parts.

- Increasing overall production speed.

- Better Material Compatibility

CNC machines can work with various rotor stack materials, including:

- Silicon steel – Ideal for reducing energy loss in high-efficiency motors.

- Cobalt alloys – Used in aerospace and defense applications.

- Nickel alloys – Preferred for high-temperature environments.

- Enhanced Quality Control

Advanced CNC machining centers use automated inspection systems to verify part dimensions, ensuring that every rotor stack meets strict industry standards.

Applications of CNC Machined Rotor Stacks

Rotor stacks manufactured with CNC precision are used in a variety of industries:

- Aerospace

Aircraft engines, actuators, and auxiliary power units require high-precision rotor stacks to function efficiently in extreme environments.

- Automotive

Electric vehicle (EV) motors and hybrid powertrains depend on rotor stacks for smooth power delivery and energy efficiency.

- Industrial Equipment

Pumps, compressors, and high-performance generators all rely on CNC-machined rotor stacks to ensure optimal performance.

- Medical Devices

High-speed medical motors, such as those used in MRI machines and surgical tools, need perfectly machined rotor stacks to operate with precision.

Conclusion

CNC machining is revolutionizing lamination rotor stacking, bringing unmatched precision, consistency, and efficiency to the manufacturing process. By using advanced cutting, grinding, and stacking techniques, manufacturers can ensure that rotor stacks perform optimally in high-demand applications.

Whether for aerospace, automotive, or industrial use, precision matters. And with CNC machining, manufacturers can achieve the highest standards in rotor stack production, ensuring longer-lasting and more efficient electric motors.