Introduction

In recent years, modular construction has gained traction in the UAE, driven by the desire for speedier, more efficient, and cost-effective building solutions. At the center of this revolution is a novel building material: the Sandwich Panel. Sandwich Panel UAE solutions are making an impact in the building industry, from temporary constructions and cold storage facilities to huge warehouses and prefabricated residences.

But why are sandwich panels such a big changer in the UAE’s modular construction industry? Let us break it down.

What is a sandwich panel?

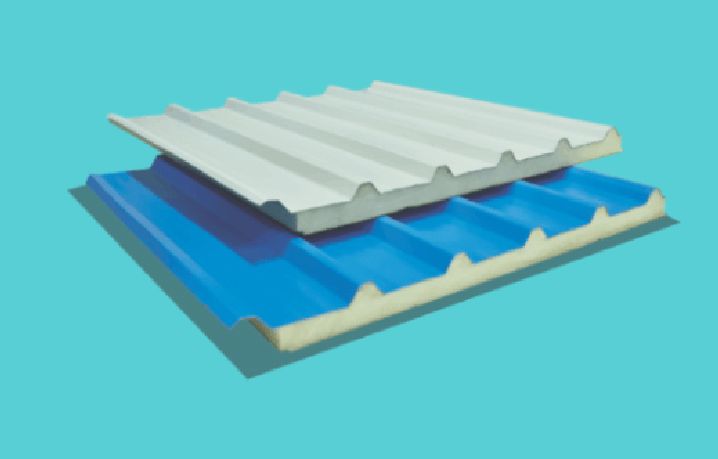

A sandwich panel is a three-layer composite construction made up of two outside metal sheets (often steel or aluminum) and an insulating inner substance like polyurethane (PU), polyisocyanurate (PIR), or rock wool. The result is a lightweight, resilient, and well insulated panel that is simple to transport and install.

These panels are often used for walls, roofs, and cold rooms in modular and prefabricated structures.

Why Sandwich Panels Are Ideal for Modular Construction in the UAE

- Speed Of Construction

In the UAE’s fast-paced climate, time is important, whether you’re creating a temporary office or a logistics hub.

Sandwich panels are prefabricated, which allows them to be easily erected on-site, significantly lowering construction time when compared to traditional building methods.

- Excellent Thermal Insulation

With high summer temperatures, thermal insulation is a primary requirement for any UAE structure.

Sandwich panels contain highly efficient core materials like as PU and PIR, which provide exceptional heat resistance, keeping interiors cooler and lowering air-conditioning costs.

- Lightweight but Strong

Despite their small weight, sandwich panels are extremely sturdy and weather-resistant.

This combination makes them excellent for modular buildings that must be moved, assembled fast, and withstand harsh desert conditions such as sandstorms and extreme UV exposure.

- Energy Efficiency

Energy efficiency is becoming a major problem in the UAE, particularly with the push for green building standards and sustainability.

Sandwich panels reduce energy consumption, which is well aligned with projects such as Estidama and the Dubai Clean Energy Strategy 2050.

- Cost-effective Building Solution

Sandwich panel-based modular construction minimizes labor costs, material waste, and on-site time.

For developers and builders, this results into more economical projects without sacrificing quality.

- Versatile Design Options

Sandwich panels come in a variety of colors, thicknesses, finishes, and core types, allowing for versatile architectural designs.

Sandwich panels can be modified for any project, whether it’s a cold room, a temporary office, or a permanent warehouse.

Sandwich Panels Are Used in the UAE Modular Construction Sector:

- Labor camps and accommodations.

- Cold Storage Warehouses

- Portable site offices.

- Retail kiosks and stores

- Industrial sheds and industries.

- Prefabricated villas and residences

From Dubai to Abu Dhabi and Sharjah, these panels are utilized to easily build both temporary and permanent constructions.

Final Thoughts: A Building Revolution is in Progress

Sandwich Panel UAE solutions are more than simply a fad; they are transforming the way buildings are designed, built, and operated in the region. Sandwich panels are changing the game in modular construction by providing unrivaled benefits such as speed, thermal insulation, and cost savings.

Sandwich panels will continue to play an important role in creating a brighter, faster, and greener future as the UAE innovates in infrastructure and sustainability.